|

Velocity measurement in stack emission monitoring is very critical and is

directly proportional to Isokinetic sampling flow rates. Thus measurement of

velocity need to be done carefully using calibrated S-type Pitot Tube and

Thermocouple- Pyrometer

Being a metallic mechanical structure two type of checks are required to be

performed on Pitot Tube.

1. Tips of both the tubes need to be physically inspected for damages in case of

damage seen Pitot Tube need to be calibrated after repair of tip.

2. Leak check of Pitot tube There should not be any leaks from joints connector

and from pipes.

Checking Procedure

With regular use of Pitot Tube fitted with push fit connectors and tubings

leakages are known to develop which need to be checked time to time for

rectification. Leak Checking is desired before each measurement.

Intermediate checks for probable leaks in Pitot with connector fitted are need

to be done to meet the requirement.

Tips of the pitot need to be carefully protected so that shape is not deformed

while handling. To perform leak check vacuum need to be created in the Pitot

either by pump or by other available system.

S marked ends of leak check adopter pipe (Fig 1) need to be connected to Pitot

Tube on push fit connector. Monitoring end of Pitot need to joined using

provided silicon pipe so that both pipes of pitot can be checked simultaneously.

Vacuum of 200+ mmHg need to be created either by pump or by other available

system. Vacuum gauge reading is used to set the vacuum in tube. Close the valve

quickly so that generated vacuum remain trap in the tube.

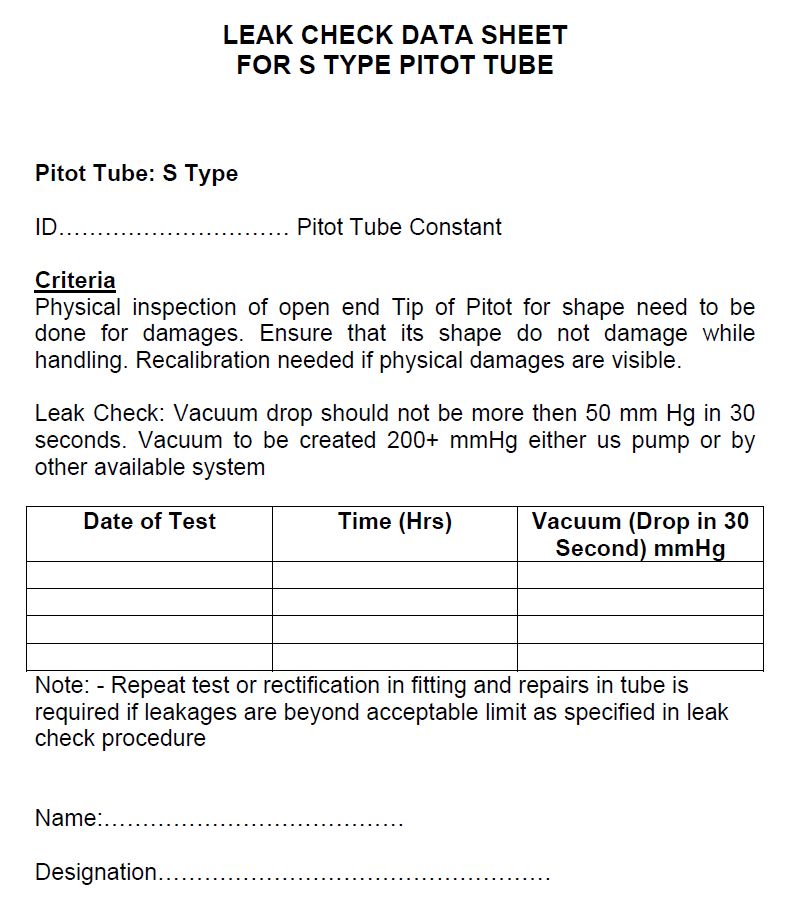

Vacuum created must remain stable and drift must not be more than 50 mmHg in 30

second. Data need to be recorded in enclosed leak check format.

|